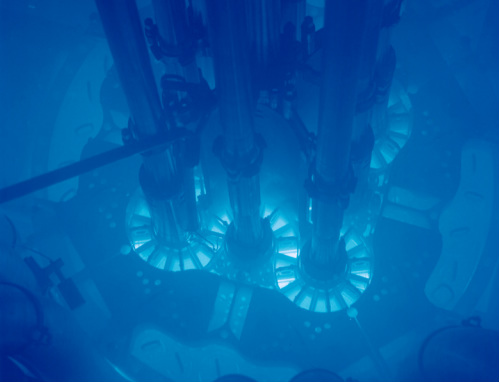

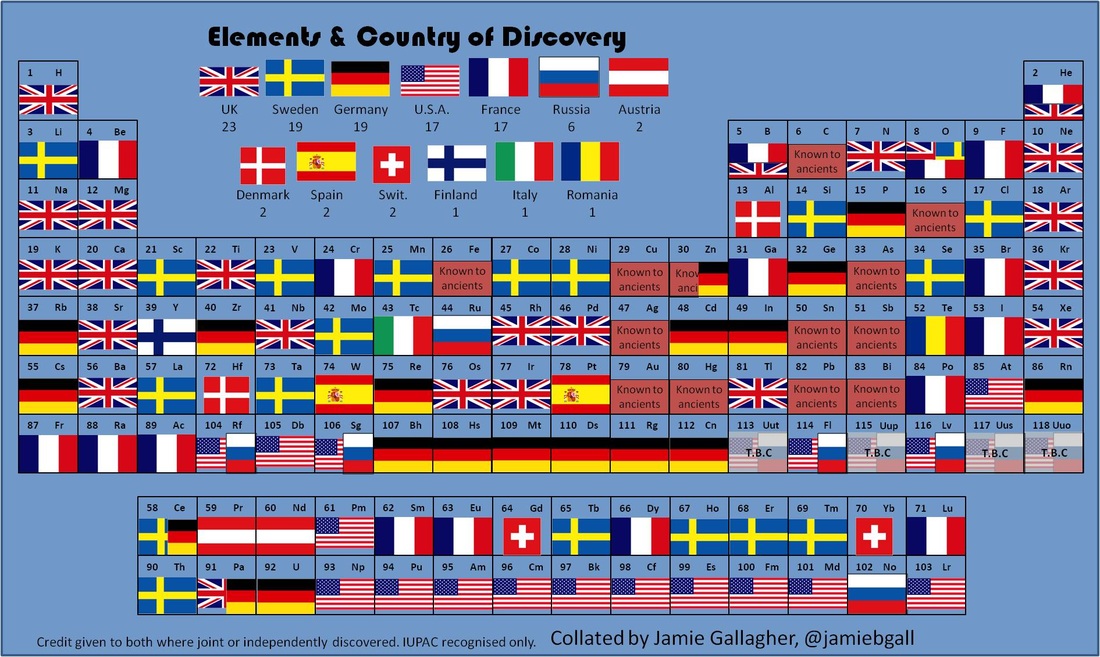

Nuclear power plants are very different than their fossil fuel counterparts both in how the energy is generated and in the day to day operations. Both nuclear power plants and fossil fuel power plants rely on generating steam to spin a turbine to generate electricity but that is where the similarities end. Fossil fuel plants rely on burning hydrocarbons, such as coal and natural gas, to generate heat to boil water while nuclear power plants rely on fission. Fission generates substantially more energy than the burning of fossil fuels, especially on a pound per pound basis. Inside of a commercial nuclear power plant, fission is the splitting of a uranium and plutonium atoms into smaller atomic pieces. By splitting these atoms, a large amount of energy is released. A fossil fuel plants works differently by chemically burning hydrocarbons into mainly water and carbon dioxide.

Have you ever seen a train carry loads of coal from a mine to a coal power plant? For a coal power plant to continue to generate electricity, coal must be constantly provided to the boiler. However, for most commercial nuclear power plants, new fuel is added to the reactor every 12 to 24 months, which denotes the cycle of the reactor. Each cycle, between a quarter and a half the fuel assemblies, which contain the uranium and plutonium for fission, are removed and replaced with new fuel assemblies. After the reactor is refueled, no fuel is added to the reactor and all the energy that will be generated during that cycle is already there, it only needs to be extracted. Since the fuel will be in the same location in the reactor for up to 24 months, placement within the nuclear reactor is very important.

For each cycle, engineers start preparing up to a year and a half in advance to determine where the fuel assemblies should be located within the core. The first step in the process is to determine how many new fuel assemblies are required and what the uranium enrichment should be. This is the most important step since the manufacture and delivery of the new fuel takes a long time to ensure that the fuel is properly manufactured and inspected prior to use. Once the fuel is built and delivered, the fuel inventory is set for the cycle and it is very difficult to make major changes to the design. During this phase, engineers will use computational tools to model the reactor core, which is made up of the fuel assemblies, to determine key characteristics of the cycle. Once a candidate design has been determined, the safety analysis for the cycle can be performed.

Due to the unique nature of nuclear power, a wide variety of safety analysis calculations are performed to ensure that the core will meet all the safety requirements as defined by the Nuclear Regulatory Commission (NRC). The calculations performed for each plant are documented in the plant’s Final Safety Analysis Report, describing all the work done to ensure the safety of the plant for a multitude of accident scenarios. Each time the reactor is refueled, engineers will perform calculations using core and plant models to show that in the event of an accident, the regulations set out by the NRC will be met. These regulations exists to ensure the safety of not only the public, but also the workers at the plant. Once the calculations have been completed, engineering reports are generated for submission to the NRC demonstrating that refueling the core continues to meet all the regulations and requirements. The safety analysis calculations that are performed each cycle are done to demonstrate that the plant can operate safely in the worst possible scenarios and during an accident.

Startup physics testing is a series of tests performed after each refueling as the reactor is brought to power to demonstrate that the reactor is actually as it was modeled. This shows that the reactor is behaving as predicted and validates the safety analysis. Specific calculations are done each cycle and compared to the results of the startup physics testing. If the plant is within a certain tolerance to the predictions, it demonstrates that the safety analysis is bounding and the plant and continue to operate. If outside of the predictions, engineers must investigate to determine what the issue is and whether or not the plant can continue to operate.

After startup physics testing, the plant will continue to operate until the end of the cycle, assuming that the predictions remain accurate. During this time, reactor operators will continue to check and ensure the overall safe performance of the reactor. Once the startup is completed, engineers will restart the process to prepare for the next reactor refueling. Overall, nuclear power plants operate on a cyclical basis with the refueling of the reactor being the main goal. Once the refueling is performed, reactor operators monitor the performance of the core to ensure safe operations while other engineers prepare to refuel the core again. The breakdown of this cyclical nature is to generate a design for the reactor cycle, demonstrate that the design can operate safely for the entire cycle, provide the necessary data for plant operations, including startup information, and then finally perform startup physics testing to validate all the work performed. After this process is completed, the reactor operators will operate the plant and ensure the safety of the reactor until the next refueling is needed.

RSS Feed

RSS Feed